Our products

Regarding the classification of medical equipment, our products are in the category of disposable medical supplies used in the group of therapeutic equipment. These products are made from medical-grade PVC granules, in which the originality of raw materials and products have been checked and confirmed by a microbiological laboratory.

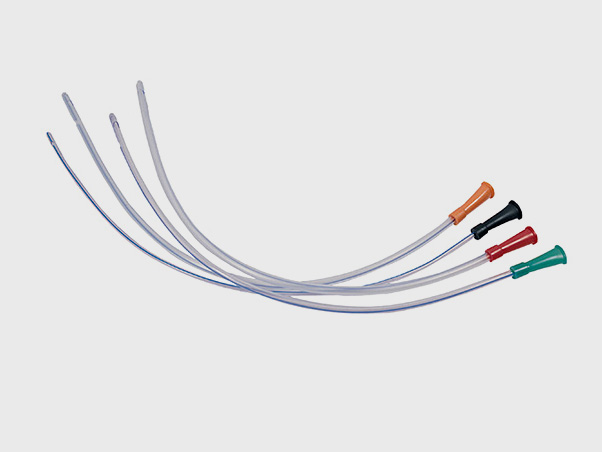

Suction Tube

Nasogastric Catheter

Nelaton Catheter

Feeding Tube

Sterile with ethylene oxide gas

The need for proper medical equipment that is sterilized safely has always been growing. New materials and equipment used in this industry always create a challenge for sterile systems and also drive sterilization technology to improve existing processes and create new methods. Meanwhile, today the use of reliable methods such as thermal sterilization, gamma rays, and sterilization with ethylene oxide gas is more widely used in medical centers and sterile service centers because of various technical reasons, compatibility, and permeability. Each of these methods has its advantages and limitations’, so choosing the right sterilization method is very important. Today, sterilization with ethylene oxide gas is known as the most widely used sterilization method in this industry.

The use of ethylene oxide sterilization as a cheap, widely used, safe sterile method is undeniable and objective observations of its use in many different hospitals in Europe and the world show that the use of this method is still widespread. And reputable European medical equipment companies consider this method as one of the most important and safest sterilization methods and take advantage of it.

Among the advantages of this method are:

- The tendency of the healthcare industry to use lighter materials in the manufacture of medical devices that are sensitive to heat, moisture, or radiation and are sterilized easily with ethylene oxide gas.

- The method of sterilizing medical equipment with high volume ethylene oxide gas is the main reason for its use in medical equipment factories.

- Due to the very high permeability of ethylene oxide gas, porous objects with apparent complexity are easily sterilized.

- One of the most important features of using the ethylene oxide sterilization method is the absence of changes in objects such as rust.

- In the case of plastics that are sensitive to sterilization by radiation and changes in their properties such as discoloration or drying of the polymer, the method of sterilization with ethylene oxide gas is widely used.

- Compatibility of this method with consumables in equipment that need to be sterilized several times.

Types of ethylene oxide sterilization methods:

1- Sterilization with diluted ethylene oxide gas

2- Sterilization in a flexible chamber

3- Sterilization with ethylene oxide gas under vacuum

To sterilize its products, Bita Salamat Paria Company uses the method of vacuum sterilization with ethylene oxide gas, which is one of the most widely used sterilization systems in the world today.

In this method, the medical equipment is placed in its final packaging and in large quantities inside the containers that can withstand a high vacuum and all vacuum sterilization steps applied to them.

Product Packaging

One of the most vital steps in producing disposable medical equipment is the packaging and sterilization process. The design of the packaging system depends on the nature of the medical device, sterile methods, expiration date, transportation, and storage of the medical device. The packaging system should be effective and safe that the sterilized product is without any defects when it reaches the final consumer.

The advantages of Beternes products packaging are:

high resistance in humid environments, a bacterial barrier against micro-organisms, ease of opening the package, minimizing lint while opening the package, preventing operator error in detecting tools inside the package, increasing quality of items inside the package, and time of staying sterile.